Principal Senior Technical Fellow Rich Aston leads a team of engineers always trying to build the proverbial better mousetrap. “We always strive to find new and better ways to innovate,” said Aston. “Learning and teaching are core values of our team.” Applying their knowledge and creativity to inventions, Aston’s team created a fully additively manufactured, or 3D-printed, metallic satellite spacecraft structure. The structural panels are lighter, require less labor and dramatically reduce cycle time compared to the design and manufacture of previous structures.

ADDITIVE ASSEMBLIES

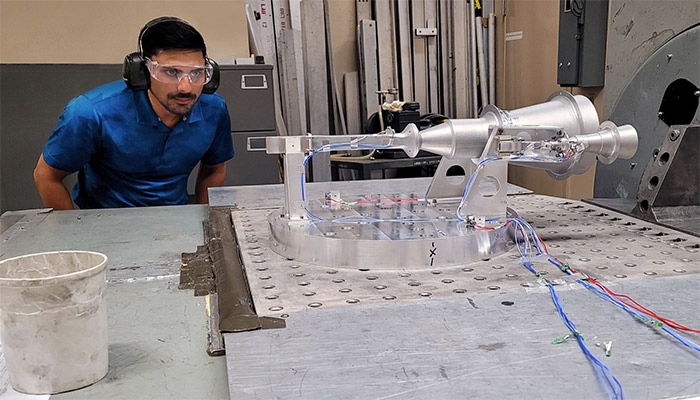

Boeing engineer Emily Woods prepares a 3D-printed satellite panel for assembly. Producing the panels with additive manufacturing reduces structure assembly time to less than one hour.

Benefits of this 3D-printed product

- The fabrication lead time for the high-strength aluminum used on the structure is days rather than months for traditional honeycomb composite panels, enabling engineers to respond faster and with more agility if a customer requests changes.

- The 3D-printed construction eliminates secondary labor operations such as match drilling and match bonding.

- The design features a roughly 99% part count reduction, reducing potential supply chain strain.

- Structure assembly time is dramatically reduced to 53 minutes, compared to weeks for a traditional composite design.

Be the first to comment on "Boeing engineers apply creativity to design a fully additively manufactured, or 3D-printed, satellite structure"