Jungheinrich Automates the Logistics Centre for DeutscheAircraft at Leipzig/Halle Airport

Hamburg/Weßling, 14 October, 2025 – Deutsche Aircraft is relying on highly automated solutions from material handling specialist Jungheinrich to efficiently and sustainably produce its new, 40-seater regional aircraft at the cutting-edge Final Assembly Line currently under construction at Leipzig/Halle Airport.

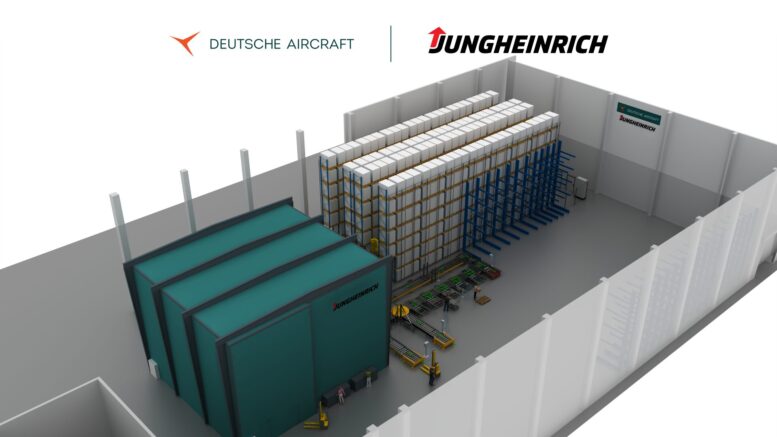

This innovative new concept consists of the space-saving Jungheinrich PowerCube container compact storage system and an automated, very narrow aisle warehouse (AutoVNA) with two aisles. Jungheinrich worked closely with Deutsche Aircraft during the design phase and impressed with a comprehensive solution from a single source, offering more sustainability, flexibility and less redundancy than alternative concepts. This forward-looking solution enables a highly efficient and flexible material flow for the CO₂-neutral production of the D328eco regional turboprop.

First-ever combination of PowerCube and AutoVNA in an industrial setting

This project marks an industry first: Jungheinrich’s PowerCube is being combined with an AutoVNA system in an industrial environment for the first time, achieving maximum space efficiency and optimal integration into existing logistics processes.

Sebastian Böhnl, Site Manager Leipzig at Deutsche Aircraft, states:

“Jungheinrich AG stands for high-tech intralogistics. They provided exactly the solution we needed in Leipzig to operate efficiently and safely. We look forward to the collaboration and taking a pioneering role with the first combination of AutoVNA and Jungheinrich’s PowerCube. We are getting closer to the future of sustainable aviation every day.”

Dr. Lars Leiking, Director Sales Operations ASRS at Jungheinrich, adds:

“With this combination, we demonstrate that highly automated systems can add real value to complex manufacturing processes. Deutsche Aircraft benefits from a flexible, scalable and energy-efficient storage structure, perfectly tailored to their needs.”

Future-oriented logistics for a sustainable aviation industry

The project at Leipzig/Halle Airport is part of Deutsche Aircraft’s long-term growth strategy. In the new Factory 4.0, CO₂-neutral production facility located on a 60,500 m² site, up to 48 D328eco aircraft will be produced annually. The facility is designed for two-shift operations which can be expanded to three shifts if needed and is scheduled for completion by the end of 2025.

Michael Rentschler, Head of Transport & Logistics at Deutsche Aircraft, says:

“We are very pleased to have Jungheinrich as a partner for this exciting logistics project. The collaboration is highly professional and we are fully prepared for the implementation phase.”

Leipzig/Halle Airport offers ideal conditions for this innovative and sustainable production concept, with 24/7 operations and international significance in air cargo. Jungheinrich’s intralogistics solution is a key component of the fully digital and paperless production facility, which will be powered by solar energy. This collaboration showcases the innovation potential of Germany and establishes Leipzig as the global launchpad for the D328eco.

Source: Deutsche Aircraft GmbH

Be the first to comment on "Jungheinrich Automates the Logistics Centre for DeutscheAircraft"