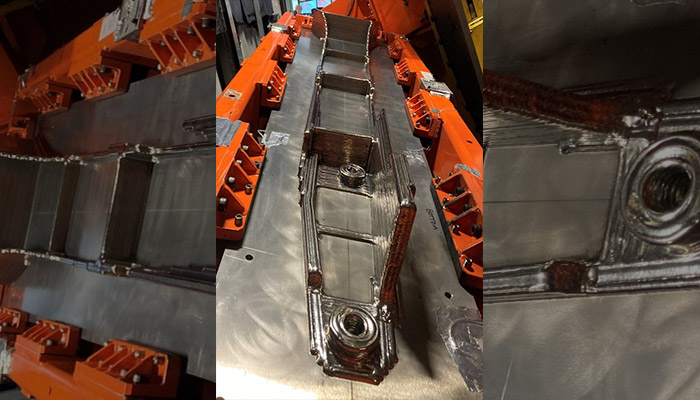

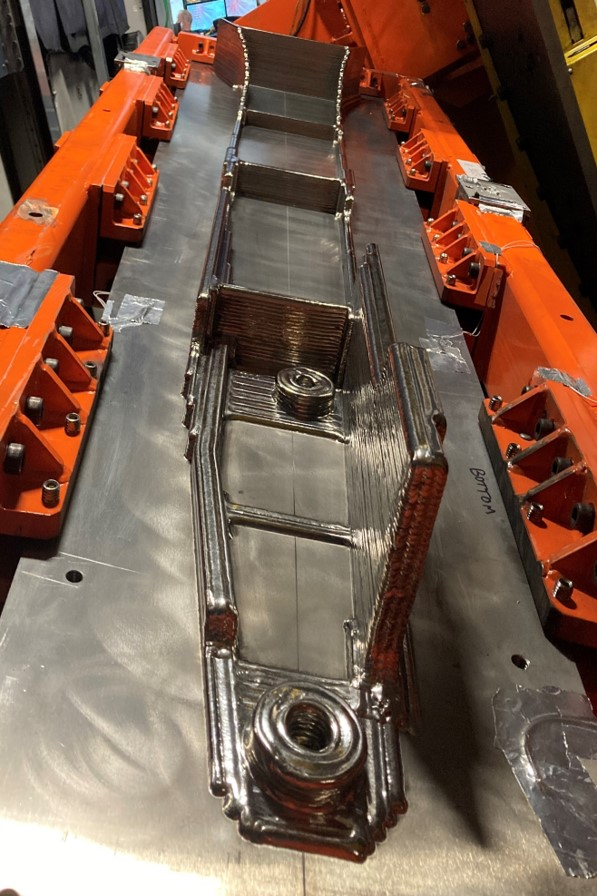

- Additively manufactured (AM) titanium aerostructure component demonstrates latest in large scale AM capabilities

- At approximately 8 feet (2.5 meters), the component is the largest additive manufactured aerostructure produced by GKN Aerospace

GKN Aerospace has completed its largest structural titanium additive manufacturing (AM) demonstration to date with the production of a component measuring 8 feet (2.5 meters) and processed from approximately 100 pounds of titanium.

The demonstration, conducted in collaboration with aircraft manufacturer Northrop Grumman, focused on the additive manufacturing process of laser metal deposition with wire (LMD-w), which successfully doubled the scale of previous components produced. The ability to scale additive manufacturing technology–also known as 3D printing—for large aerostructure components has a wide range of aerospace and defense applications. Additionally, the technology enables components to be produced faster than current methods, uses raw materials more efficiently, and may ultimately result in reduced costs.

“This collaborative milestone demonstrated cutting-edge manufacturing methods to build large aircraft components,” said Francisco Flores, vice president, production operations, Northrop Grumman Aeronautics Systems. “Additive manufacturing technologies, combined with digital transformation and analysis capabilities are enabling novel approaches to design and advanced manufacturing processes.”

Manufacturing of this component took place at GKN Aerospace’s AM Centre of Excellence located at the U. S. Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory (ORNL). Demonstrations like this are vital to enabling full industrialization of the LMD-w process for aerostructure components which feature complex geometry found in titanium aerostructure designs.

Shawn Black, President of GKN Aerospace Defense Business said: “This achievement further advances GKN Aerospace’s research into laser metal deposition, expanding on the material science and process development for aerostructure and engine components. We appreciate the opportunity to work with Northrop Grumman to accomplish this milestone in large scale additive manufacturing.”

GKN Aerospace opened its second US-based LMD-w cell at Oak Ridge in 2019 as the world’s largest pilot production cell of its kind, focused on research and development of large scale structural aircraft components. A third AM cell – the largest at 5m by 2m in size – will follow before the end of 2022, as GKN Aerospace continues to push the boundaries of additive technology.

GKN Aerospace is already a world-leader in LMD-w technology for complex engine components from its Global Technology Centre in Trollhättan, Sweden. Future applications of AM for large-scale aerostructures will include: product development, low-rate initial production and the transition of technology development into production solutions. GKN Aerospace already has additive manufacturing components flying on major platforms across civil, military, and space markets.

Editor’s notes:

GKN Aerospace is the world’s leading multi-technology tier 1 aerospace supplier. As a global company serving the world’s leading aircraft manufacturers, GKN Aerospace develops, builds and supplies an extensive range of advanced aerospace systems, components and technologies– for use in Defence and Commercial aircraft ranging from helicopters, business jets, passenger planes to the most advanced fighter aircraft. Lightweight composites, additive manufacturing, innovative engine systems and smart transparencies help to reduce emissions and weight on the aircraft and enhance passenger comfort. GKN Aerospace is market leading in aerostructures, engine systems and operates in 12 countries at 38 manufacturing locations employing approximately 15,000 people.

Be the first to comment on "GKN Aerospace – Northrop Grumman collaboration achieves additive manufacturing milestone"