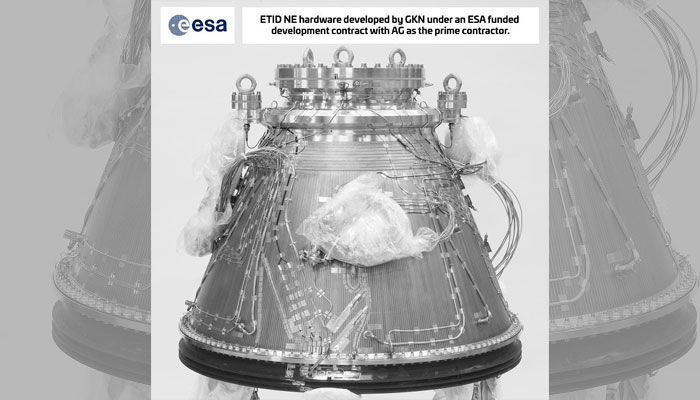

Expander Technology Integrated Demonstrator (ETID) featuring patented sandwich wall technology has successfully demonstrated its potential for future upper stage engine applications in hot-fire tests

The ETID Nozzle Extension builds on GKN Aerospace’s patented manufacturing method for actively cooled nozzle extensions, i.e. the so-called “Sandwich” laser welded channel wall technology. The sandwich has a reinforcement jacket using additive manufacturing in the form of laser wire deposition. ETID is part of the ESA funded Future Launcher Preparatory Programme guiding Europe’s next-generation upper-stage rocket engine design

These technologies have matured over almost two decades of continuous improvement in GKN Aerospace’s center of excellence in Trollhättan Sweden and it shows clear customer benefit in liquid rocket propulsion applications. Some key operations of the manufacturing of the ETID Nozzle have been performed and developed in close cooperation with Force Technology in Denmark.

The program is currently hot-fire testing at DLR’s P3.2 test facility in close collaboration with ArianeGroup, Ottobrunn. The test campaign has completed the run-in tests and the first test block with excellent results. The second block with additional technologies and with extended duration of the tests has also been successfully completed. After completion of the third test phase the ETID NE technology is ready to target future upper stage flight applications.

Henrik Amnell, Program Manager, Space Future Programs at GKN Aerospace Engine Systems, says: “This successful series of hot-fire tests proves the progress we’ve made in our sandwich wall technology. This really validates our approach to deliver high quality affordable products with high reliability and low maintenance costs. Incorporating this technology will enable us to reduce significantly production lead times and make our products more cost competitive.”

J.N. Caruana, manager of demonstrators in the Future Launcher Preparatory Programme of ESA Space Transportation, says: “GKN Aero masters the technologies and modelling tools that enabled the design and manufacturing of an excellent nozzle for a hydrogen expander-cycle engine. This nozzle is working perfectly at the hot-fire test stand. It meets its demanding mass and heat pick-up requirements. This prepares for cutting-edge evolutions towards more competitiveness of our upper stage engines in Europe.”

Editor’s notes:

GKN Aerospace is the world’s leading multi-technology tier 1 aerospace supplier. As a global company serving the world’s leading aircraft manufacturers, GKN Aerospace develops, builds and supplies an extensive range of advanced aerospace systems, components and technologies– for use in aircraft ranging from helicopters and business jets to the most used single aisle aircraft and the largest passenger planes in the world. Lightweight composites, additive manufacturing, innovative engine systems and smart transparencies help to reduce emissions and weight on the aircraft and enhance passenger comfort. GKN Aerospace is market leading in aerostructures, engine systems, transparencies and wiring systems and operates in 15 countries at 51 manufacturing locations employing approximately 17,000 people.

GKN Aerospace in Trollhättan Sweden is the center of excellence for design and manufacturing of cooled Nozzle Extensions and turbines for the Ariane 5 and Ariane 6 space launcher programmes. GKN Aerospace has over 40 years of experience of designing and manufacturing products for the space industry.

Be the first to comment on "GKN Aerospace demonstrates new nozzle technologies for future upper stage launcher engine"