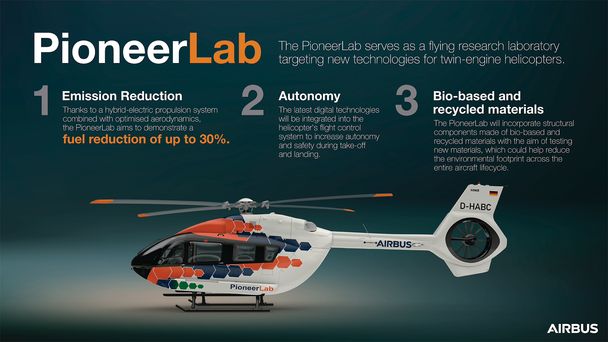

Airbus Helicopters’ third flying laboratory, the PioneerLab will be used as a testbed for technologies that are currently being researched.

Arriving as Airbus Helicopters’ third flying laboratory, the PioneerLab, a legacy H145, will be used as a testbed for technologies that are currently being researched. Airbus Helicopters’ Rotor Magazinediscovers: ‘What will it test that couldn’t be done on the existing FlightLab or DisruptiveLab?‘

“This is a good question!” according to Dominik Strobel, Programme Lead for PioneerLab. “Of course, from a technology side, we can test anything. However, it helps if we utilise the idea of a testing pyramid. You start with the fundamental demonstration tests on the ground. At the peak of the pyramid, however, you have to bring it to a platform, and you simply cannot test everything on a single-engine helicopter if it is ultimately meant for a twin-engine helicopter. They have different requirements, sizes, you have to integrate things in a different way and the systems are different. There are many reasons why the twin-engine PioneerLab makes sense.”

What’s in the test?

The PioneerLab will test new technology in three areas: emission reduction, autonomy and sustainable materials and Strobel is keen to point out that it will not simply be testing existing technology for a larger platform. “If we look at the RSAS system, it is an enhanced system on what we have previously done – the requirements are different and therefore we will scale up on what we already have on the RSAS system. The goal is to improve the existing technologies to make them valuable for the targeted platform. On the other side, there are technologies like the automated take-off and landing (ATOL) and there is a need for this on twin-engines due to the higher integration of the systems and functions. Using a lot of different technologies, we are preparing how to integrate an easy method of doing a fully automated take-off and landing into the helicopter.”

Emission reduction is a target not without its challenges, as Strobel explains: “Our aerodynamics are already quite advanced, so it’s difficult to make advances there but improvements to the airframe and empennage are possible.” The research does have one highly significant goal though, “we are looking for the next possible evolutions and especially at hybridisation. We are hoping to bring the engine to a more efficient point, throughout the whole flight, with an e-motor taking over spikes and inefficient areas of flight, which will lead to an emission reduction.” The third area of interest is in terms of testing materials that are more sustainable. “Bio-based items will be introduced which will enable us to recycle parts of the aircraft”, notes Strobel.

Shared success thanks to the German ‘Lab’

This is also the first flying laboratory to be based in Donauwörth, Airbus Helicopters’ German site and with reducing emissions a priority for the country, the government is supporting the PioneerLab’s research, with projects partly co-funded by the country’s Federal Ministry of Economic Affairs and Climate Action, via LuFo. To Strobel it makes perfect sense to situate the PioneerLab at the Donauwörth site but he is keen to stress that its research will benefit the entire company. “The heart of the light twin-engine helicopters is in Germany so it makes sense to locate it here but we have a lot of support from across the business and our ambition is to have an open, transparent project. The technologies we are researching and our findings will bring value and knowledge to every programme.” Indeed Strobel states that programmes integrating the research into tangible innovations is a key indicator of success. For Strobel, hybridisation will also be an important measure “though the timeframe is much longer, my ambition is to see it become part of the fleet in some form or another.”

Be the first to comment on "A flying lab for twin-engine helicopters"