Perfect fit: Tailoring T-7A Red Hawk’s cockpit for the missionHow volunteers of various heights, sizes helped U.S. Air Force make the advanced trainer’s crew station more accessible. Perfect fit: Tailoring T-7A Red Hawk’s cockpit for the missionHow volunteers of various heights, sizes helped U.S. Air Force make the advanced trainer’s crew station more accessible. |

Above: T-7A Red Hawk program Boeing office administrator Christy McKey volunteered to be measured inside the cockpit of the U.S. Air Force advanced trainer. The Air Force Airmen Accommodation Lab asked for volunteers of various heights and body proportions. McKey is 5 feet, 1 inch (1.5 meters) tall.

Trading her street clothes for a flight suit, Boeing T-7 programs office administrator Christy McKey climbed into a T-7A Red Hawk on a mission to help make the crew station of the aircraft more accessible and workable for future student fighter and bomber pilots. The U.S. Air Force Airmen Accommodation Lab at Wright-Patterson Air Force Base, Ohio, asked for 20 volunteers with statures ranging from approximately 5 feet (1.5 meters) to 6 feet, 3 inches (1.9 meters) to represent pilots and test out the operating crew space in the cockpit. More than 60 T-7A teammates volunteered for the opportunity to assist the Air Force lab.

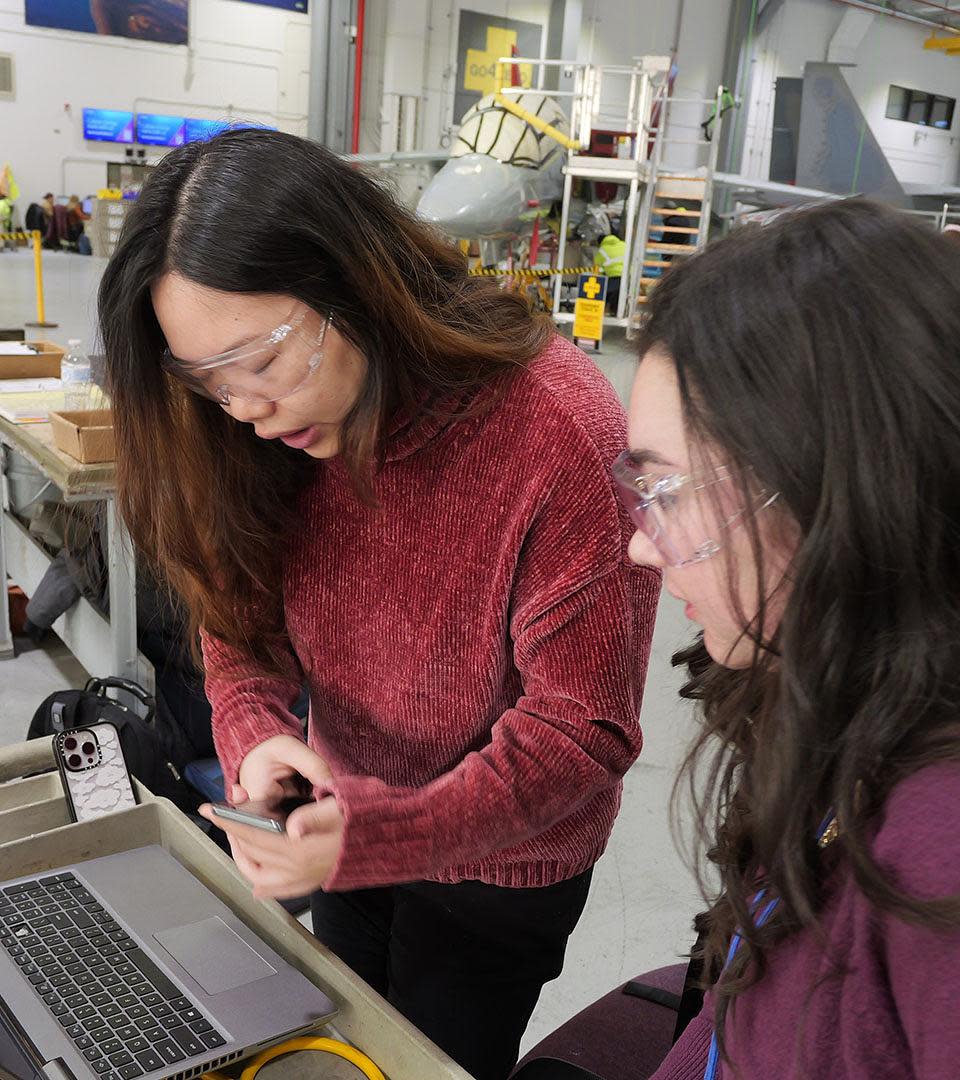

The T-7A Red Hawk is digitally designed to accommodate seven different anthropometric cases that, together, represent extremes of body size and proportion across a general military population.“Testing out the anthropometric design of the T-7A Red Hawk is extremely important when it comes to making sure we can accommodate future pilots and the Air Force can attract a larger number of candidates to train for the fight,” said Allison Chang, Boeing T-7A human factors engineer. In fact, the T-7A Red Hawk will accommodate more than 95% of all pilot candidates in the U.S. Air Force population. Allison Chang (far left), Boeing T-7A Red Hawk Human Factors engineer, and Sarah Hollis, U.S. Air Force Airmen Accommodation Lab lead engineer, study data coming in from the advanced trainer’s cockpit occupant testing.

The experience for McKey took about two hours. A laser 3D-measurement device mounted to a portable measuring machine precisely moved and calculated the distance of her outstretched arm reaching for the instrument panel as it simultaneously scanned body contours in cockpit.

|

|

Top: Justin Bowens, with the U.S. Air Force Accommodation Lab, Wright-Patterson AFB, Ohio, uses a laser 3D-measurement device mounted to a portable measuring machine to precisely determine clearance distances inside the T-7A cockpit. Above: Sarah Hollis (left), U.S. Air Force Airmen Accommodation Lab lead engineer, measures the reach of Kennedy Woodard, Boeing Phantom Works structural analysis engineer. Woodard volunteered for the testing to gain a greater understanding of structural designs and to support the team’s project.

“Supporting the T-7A Red Hawk program every day from my desk looks very different from sitting in the cockpit,” said McKey, wearing a fitted G-suit. “The opportunity to participate in this hands-on study was one I couldn’t pass up, both for the experience and the important mission it serves.”

This is the final stage of the design process that began with 3D computer-aided design models of the cockpit and 3D human manikins, then moved to physical mock-ups and prototypes, and finally to a production-ready aircraft.

|

Christy McKey, Boeing T-7A Red Hawk office administrator, fitted in a G-suit and helmet, helps the U.S. Air Force Airmen Accommodation Lab team collect accurate measurement data on the cockpit working space of the advanced trainer.

he data collected over the weeklong session will now be analyzed by the U.S. Air Force team to validate the pilot workspace of the T-7A Red Hawk advanced trainer’s crew station for future missions. Story and photos by Randy Jackson

Source: BOEING

Be the first to comment on "Perfect fit: Tailoring T-7A Red Hawk’s cockpit"