Frankfurt, Germany—November 18, 2024—At Formnext 2024, 1000 Kelvin(Hall11.1, D39), a leader in AI-driven additive manufacturing (AM) solutions, is proud to announce that its flagship AI co-pilot, AMAIZE, has expanded far beyond toolpath automation to include nearly the entire metal laser powder bed fusion (LPBF) workflow. With AMAIZE 2.0, 1000 Kelvin continues to redefine the capabilities of additive manufacturing, making the 3D printing process more reliable, efficient, and scalable for manufacturers across industries.

Advancing Automation for Greater Efficiency

AMAIZE 2.0 now features a comprehensive suite of advanced automation tools designed to tackle some of the most persistent challenges in AM. These include:

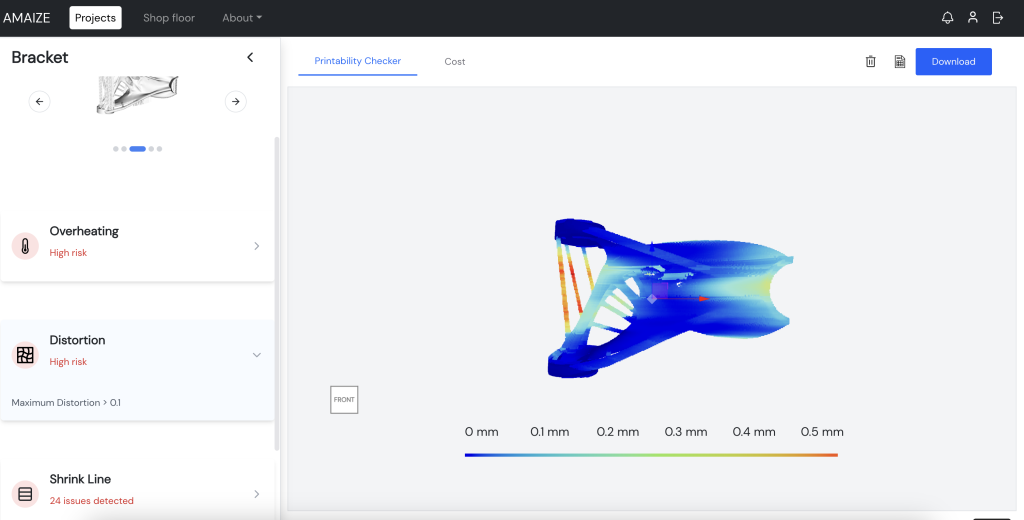

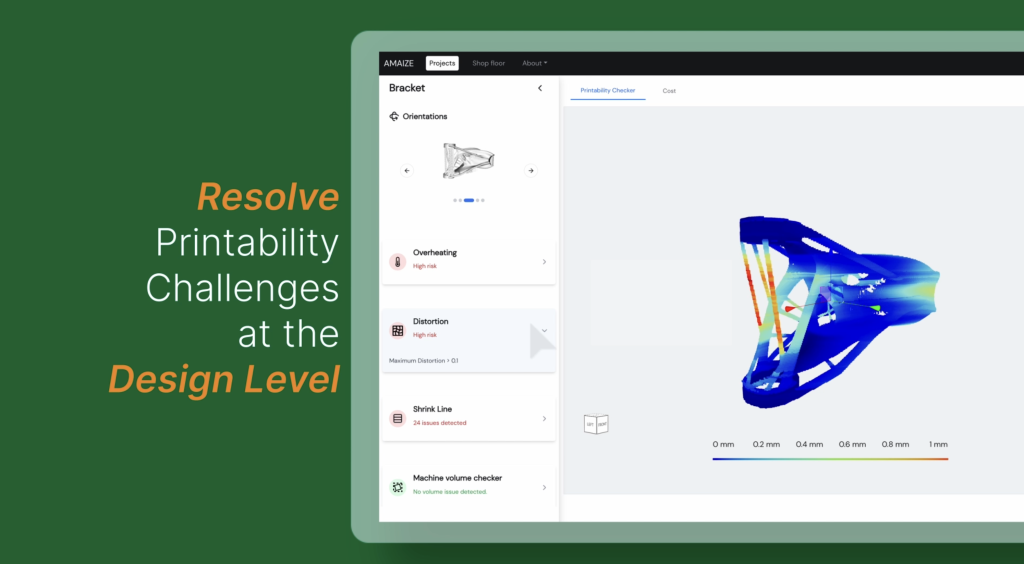

- Printability Checker: Automatically validates and optimizes designs for AM, reducing redesign cycles by 40%.

- Cost Estimator: Delivers accurate, upfront cost estimations, improving quotation accuracy by 30%.

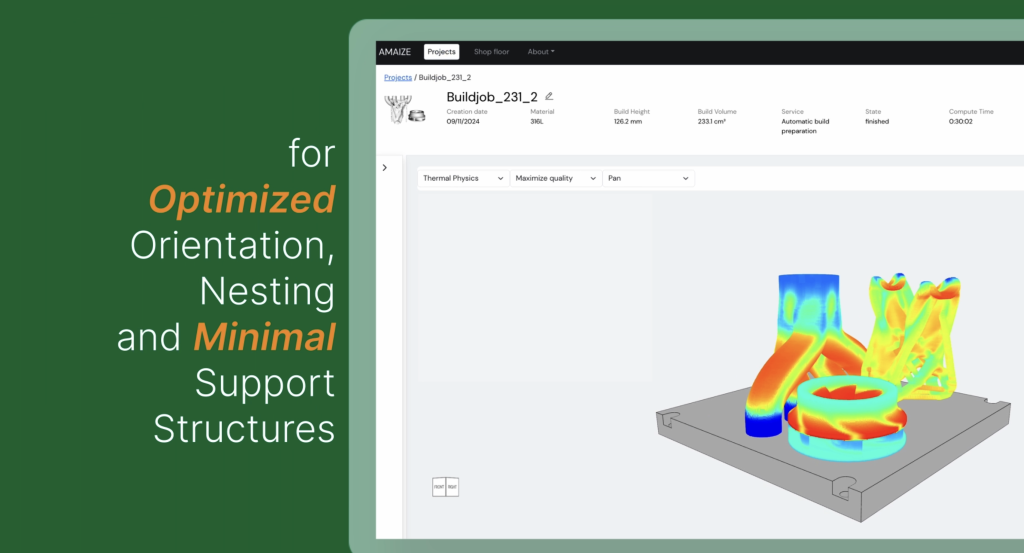

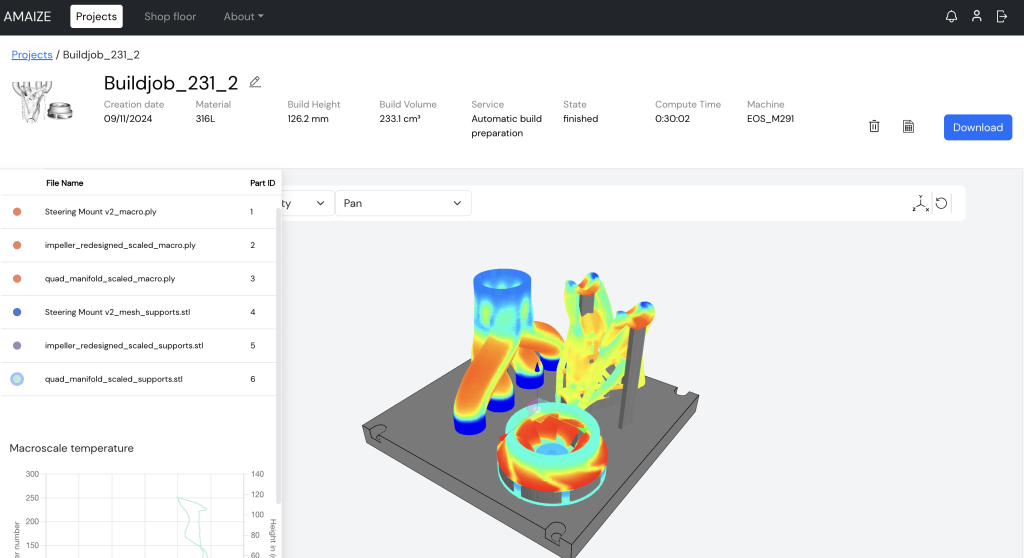

- Automated Support Structures: Incorporates physics-based build preparation to save up to 20% in material costs and enable non-experts toeasily implement successful print preparation workflows.

- Exposure Strategy Optimization: Ensures first-time-right prints with AI-driven parameters, cutting failure rates by 50%.

These enhancements allow manufacturers to unlock higher Overall Equipment Effectiveness (OEE) and increase yield by leveraging AI-powered insights for every step of the printing process.

“Our mission is to make additive manufacturing simpler, more accurate, and more predictable,” said Dr. Omar Fergani, PhD,Co-founder and CEO of 1000 Kelvin. “With AMAIZE 2.0, our customers can achieve consistent, first-time-right results with greater confidence and speed. We’re finally unlocking the true value of the 3D printing industry.”

A Proven Track Record with Key Industry Players

AMAIZE has already demonstrated its impact with customers in key industries. 1000 Kelvin’s clients, ranging from leaders in aerospace and automotive to contract manufacturing, have reported substantial improvements in both efficiency and output quality. AMAIZE 2.0 is available for early adopters, which already include such key companies as EMERSON, HENNgineered, FKM, A*Star, andUltimetal, among many others.Looking Forward

1000 Kelvin continues to lead the way in AI-driven advancements for the AM industry. As manufacturers face increasing demands for agility, reliability, and scalability, AMAIZE remains the go-to solution for delivering “first-time-right” results. The updates introduced at Formnext 2024 underscore 1000 Kelvin’s vision of transforming 3D printing into a streamlined, automated, and intelligent process.

About 1000 Kelvin

1000 Kelvin is an AI-driven additive manufacturing solutions provider, specializing in metal and polymer 3D printing. Its AI-powered software, AMAIZE, delivers “first-time-right” results by performing co design, automated build preparation and optimizing print recipes and predicting errors, significantly reducing costs and lead times in industrial production. With a presence in Berlin and Boston, 1000 Kelvin partners with leading industries to unlock the full potential of additive manufacturing.

Be the first to comment on "1000 Kelvin Unveils Completely AI-Automated Build Prep Workflow for Metal 3D Printing"